Advanced Glass Solutions for Automotive Mirror Glass

Our Product Range

Complete mirror glass solutions for automotive applications with precision manufacturing and quality assurance

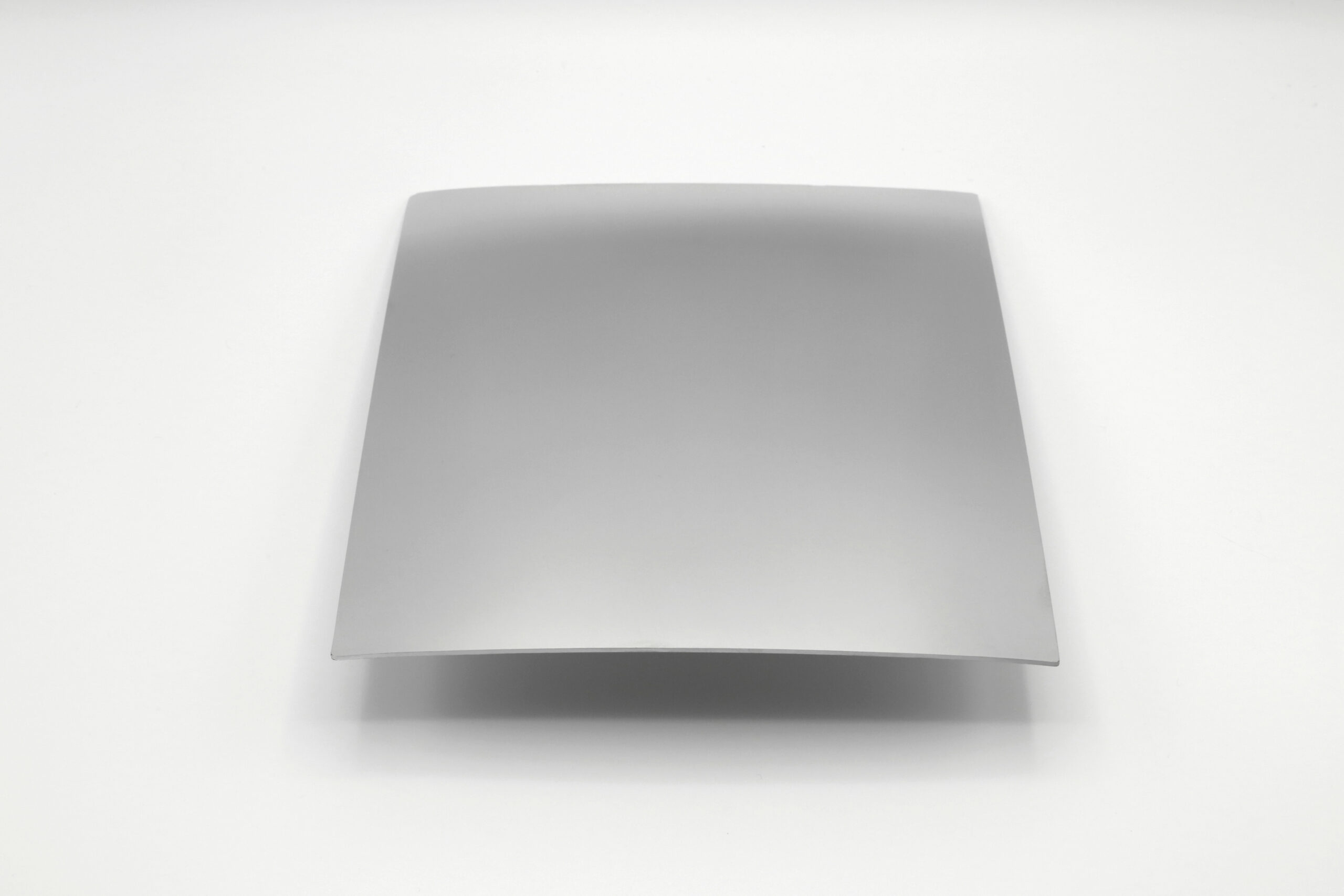

Side Mirror Glass

Stable curvature (e.g., R1230±30 / R1260±60), dense Cr coatings, laser-cut & chamfered edges; blue-tint and multi-language laser marking available.

Truck Mirror Glass

Upper: R1800–R2000 / R1400–R1500; Lower/Side: R120–R1000; large formats up to 480×250 / 457×305 mm with stable deep-curvature cutting.

Two-Wheel Mirror Glass

High value with laser cutting and high material utilization; durable Al mirrors; vivid finishes (purple/blue/gold/white).

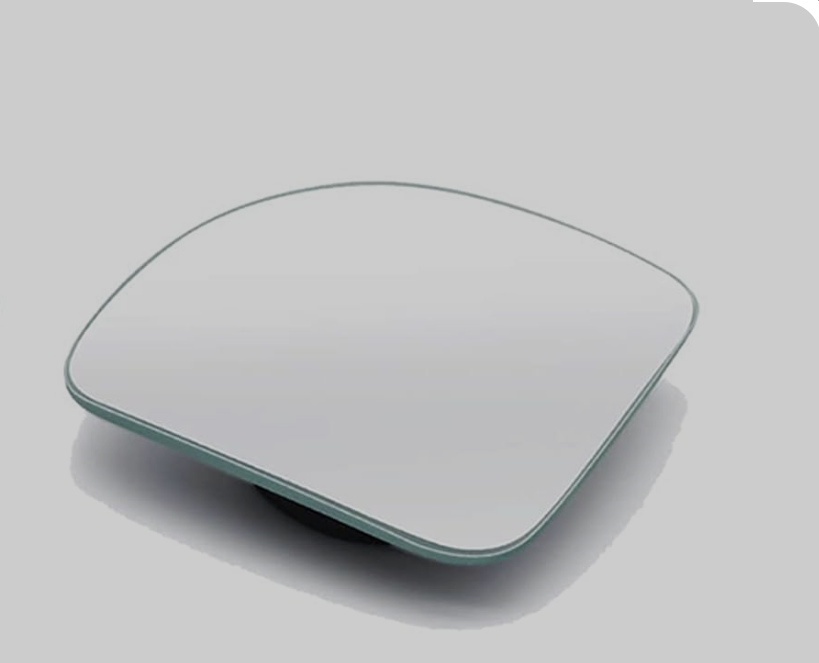

Blind-Spot Mirror Glass

Four curvatures — R120 / R150 / R220 / R320 — to expand side-view coverage; smooth laser-cut edges; optional icons/text marking.

Interior Mirror Glass

Flat / Curved (R1260±60, R1800–2000) / Prismatic; safety-back film + front protective film; assembly-friendly edges.

Convex Mirror Glass

Full curvature coverage R220–R2000; Al/Cr/Blue coatings; common sizes 203×270 to 457×305 mm; material utilization ≥90%.

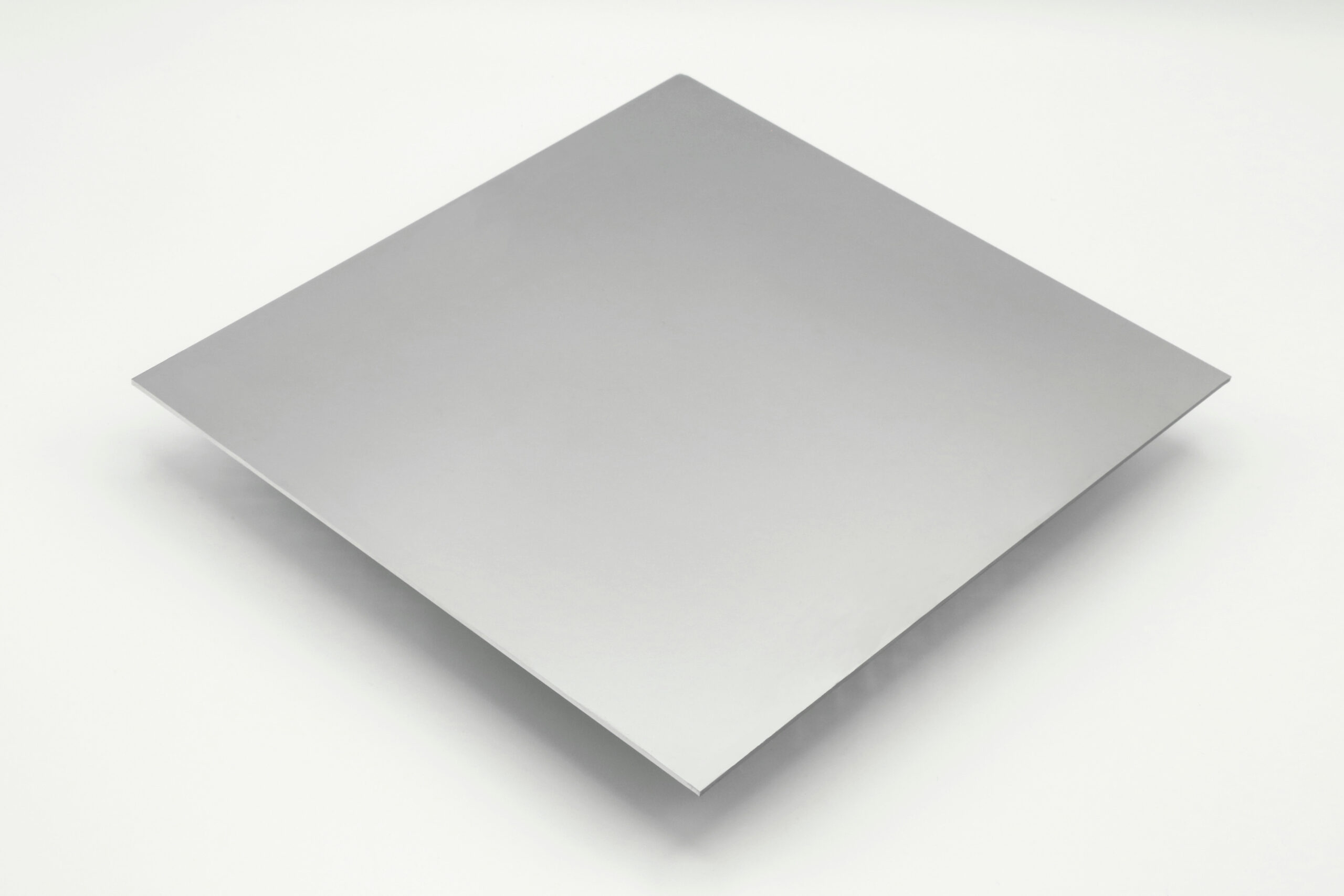

Flat Mirror Glass

Large plates up to 407×610 mm; Al/Cr/Blue coatings with uniform tone; packaging engineered for transit safety.

Why Choose Micmirror

Integrated manufacturing capabilities with quality assurance and engineering collaboration for automotive mirror glass solutions

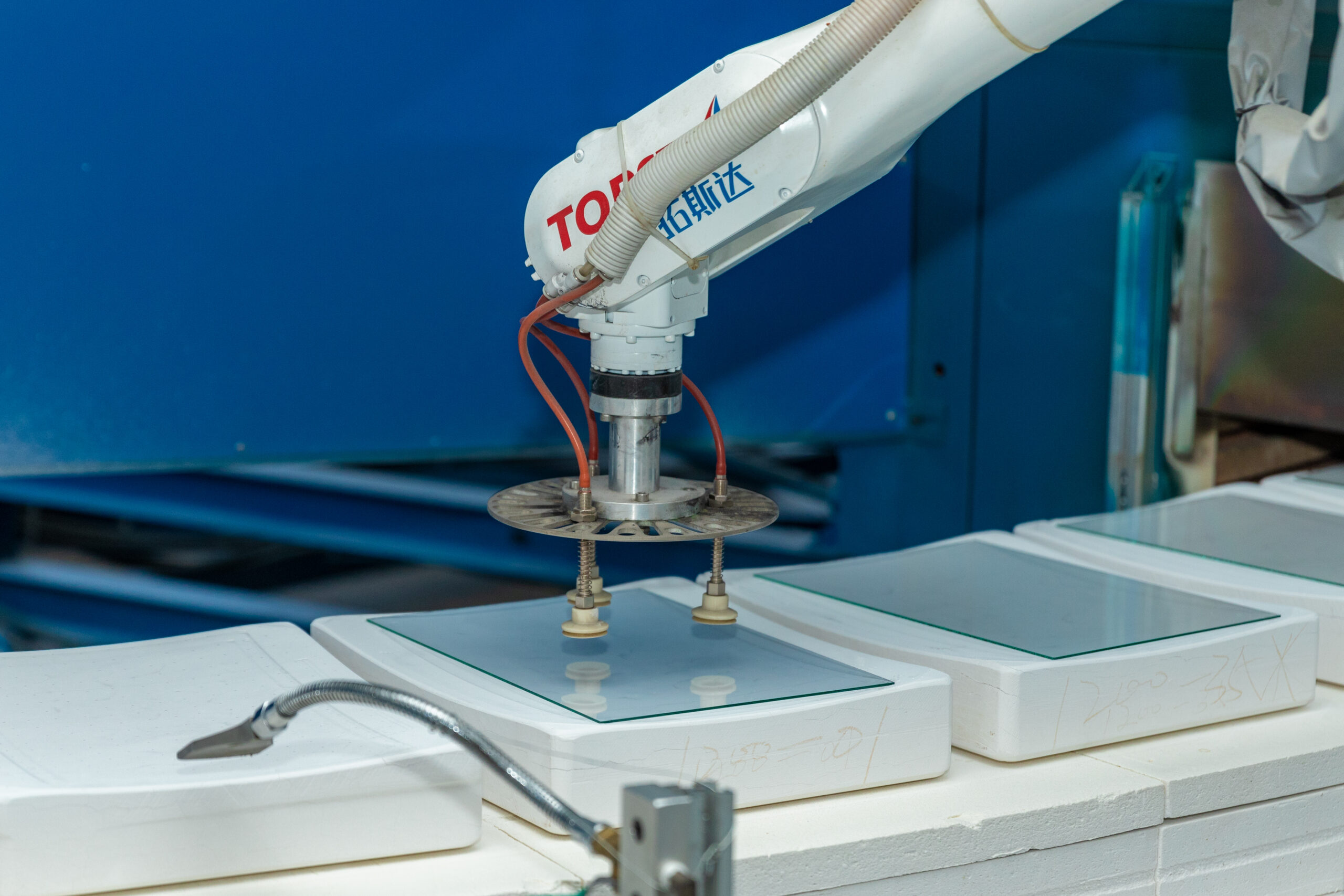

Integrated Manufacturing

Hot bending → sputtering → laser cutting → chamfering → pure-water cleaning → inspection & lab validation — all in one flow, tuned for both flexibility and scale.

Deep-Curvature Capability

Large curvature and large format parts remain consistent in curvature and cosmetics; smooth edges make assembly easier.

Quality & Compliance

SPC/GRR/control plans/visual standards; PPAP ready; third-party restricted-substance reports; global compliance support for rapid platform launches.

Engineering Collaboration

Quality planning → rapid sampling → validation → window freeze → ramp-up → stable mass production, with ongoing cost-down and continuous improvement.

Process Highlights

Advanced manufacturing processes ensuring superior quality and precision in every mirror glass product

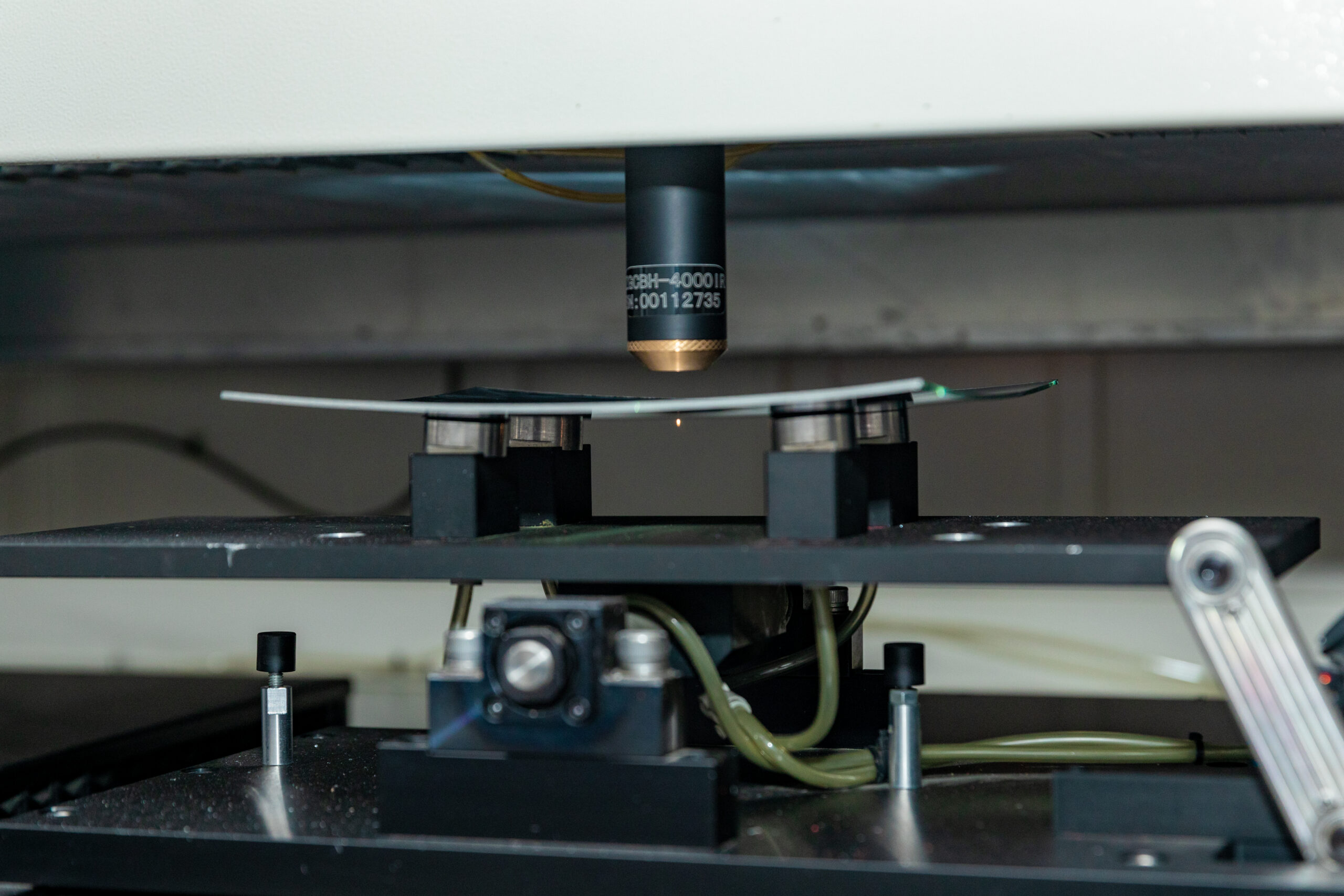

Curvature Control

Multi-zone heating curves + 3D curvature metrology; tight single-piece spread.

Dense Coatings

Cr/Al/Blue options with stable reflectance and pure chroma; corrosion/chemical/thermal-shock resistance.

Deep-Curvature Laser Cutting

Smooth, burr-free, crack-free edges to reduce assembly damage and long-term failures.

Pure-Water Cleaning

Low ions/particles; mass-production targets: zero bubbles, no white spots, no scratches.

Manufacturing Excellence

State-of-the-art facility with advanced production capabilities

Labs & Documentation

Comprehensive testing and validation with complete traceability and compliance documentation

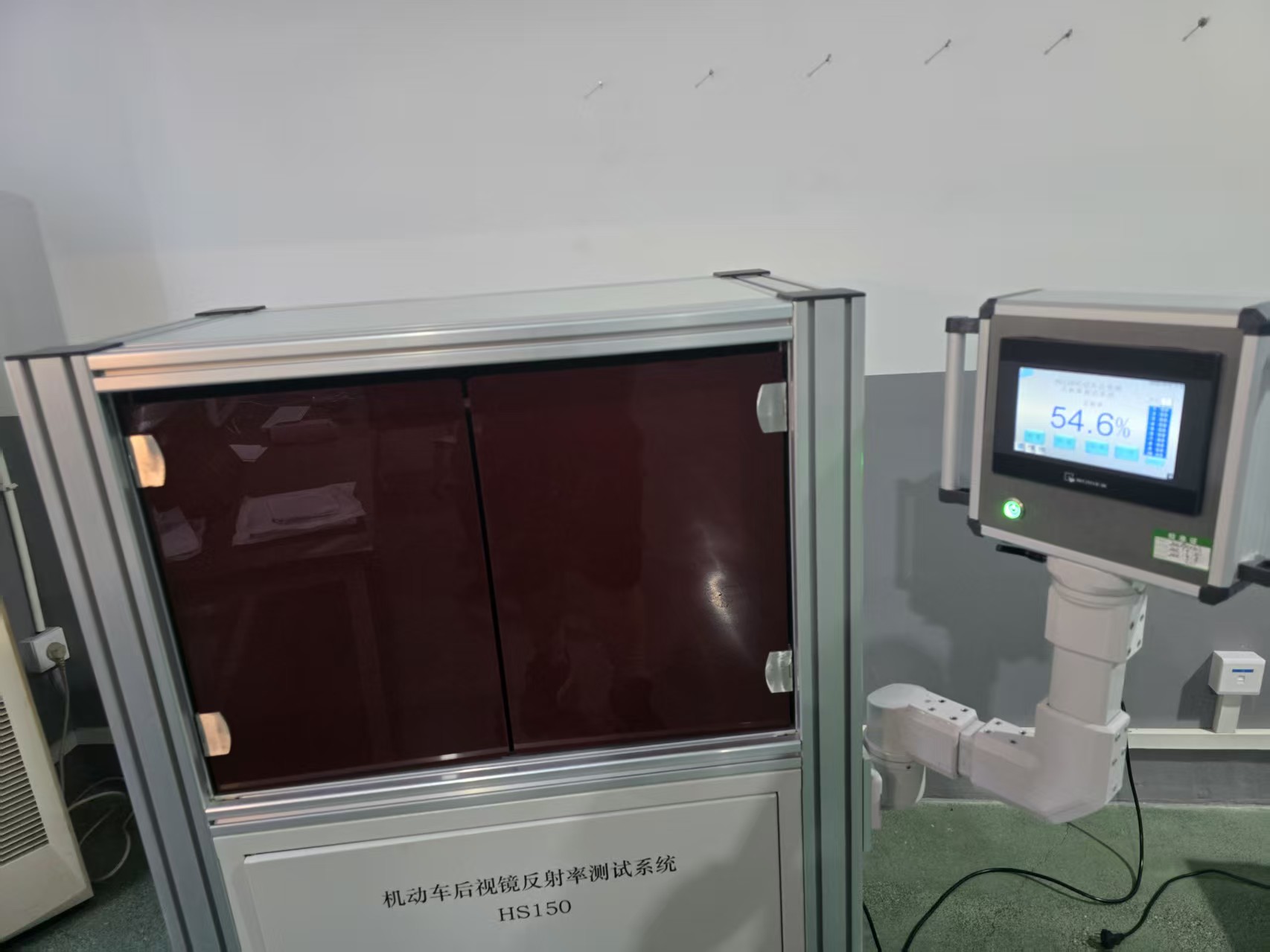

Validation Matrix

Curvature, distortion, reflectance, chromaticity, adhesion (cross-hatch), salt spray, thermal cycling/shock, etc.

Original Data with Traceability

PPAP pack (DVP&R, test records, material declarations, PSW).

RoHS/REACH & Automotive Support

Restricted-substances support and global compliance for automotive applications.

Typical Applications

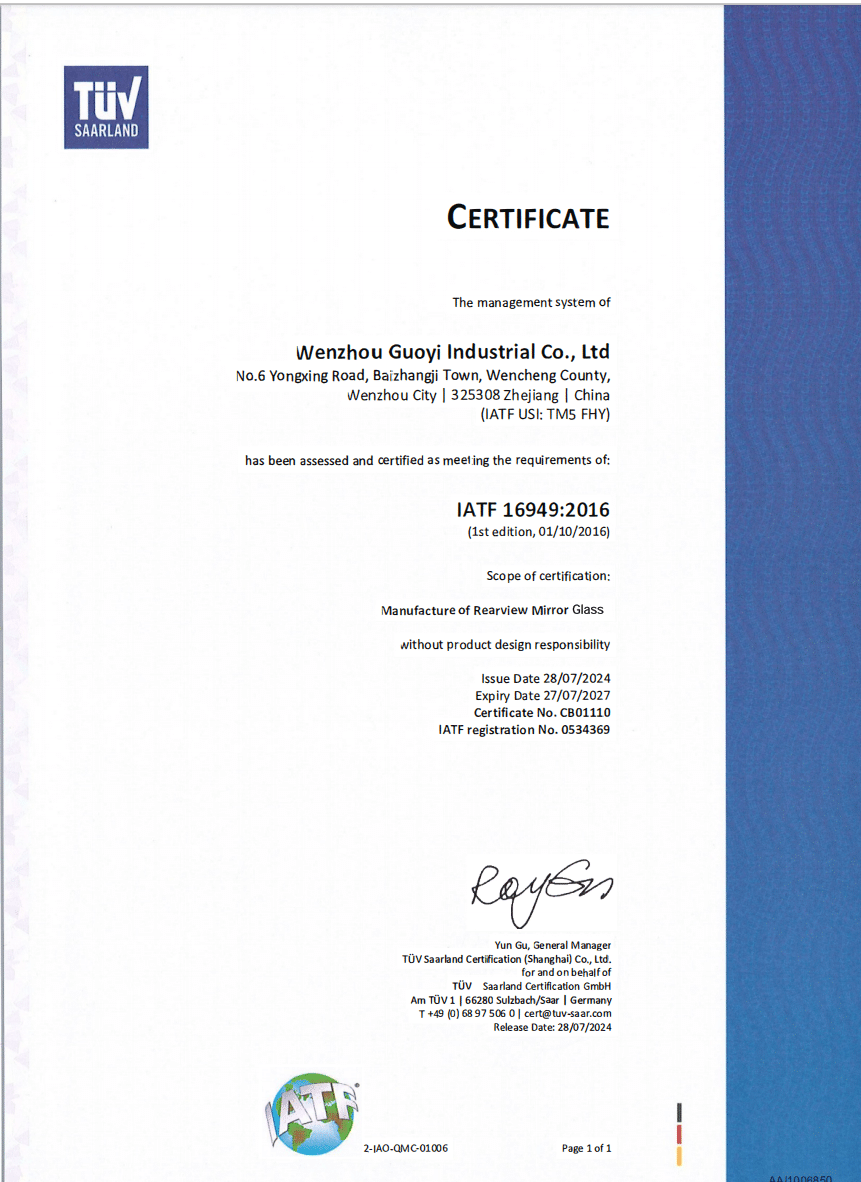

Certifications & Recognition

Validated quality systems and industry recognition ensuring reliable, compliant automotive mirror glass solutions

Quality Management

IATF 16949:2016

Environmental Management

ISO 14001

Quality Systems

Enterprise Recognition

Global Footprint

Wide product coverage across continents, trusted by leading automotive manufacturers worldwide

Southeast Asia

India, Thailand, Malaysia, Indonesia, Philippines

Europe

Germany, France, Italy, Spain, Eastern Europe

Americas

USA, Canada, Brazil, Mexico, Argentina

China Domestic

Leading OEM supply chains nationwide

Trusted by Industry Leaders

Serving major automotive manufacturers with premium mirror glass solutions

Start Your Mirror Glass Project

Get samples, technical specifications, and engineering support for your automotive mirror glass requirements