Flat mirror glass blanks for cutting

Large formats, clean cosmetics, consistent coating

Flat glass mirror blanks up to 407×610 mm, in Al / Cr / Blue coatings and 2.0 / 2.5 / 3.0 mm thickness; packaged for long-haul transit safety and high yield downstream.

Big size envelope (up to 407×610 mm) for efficient nesting

High appearance quality—no bubbles/white spots; high pass rate

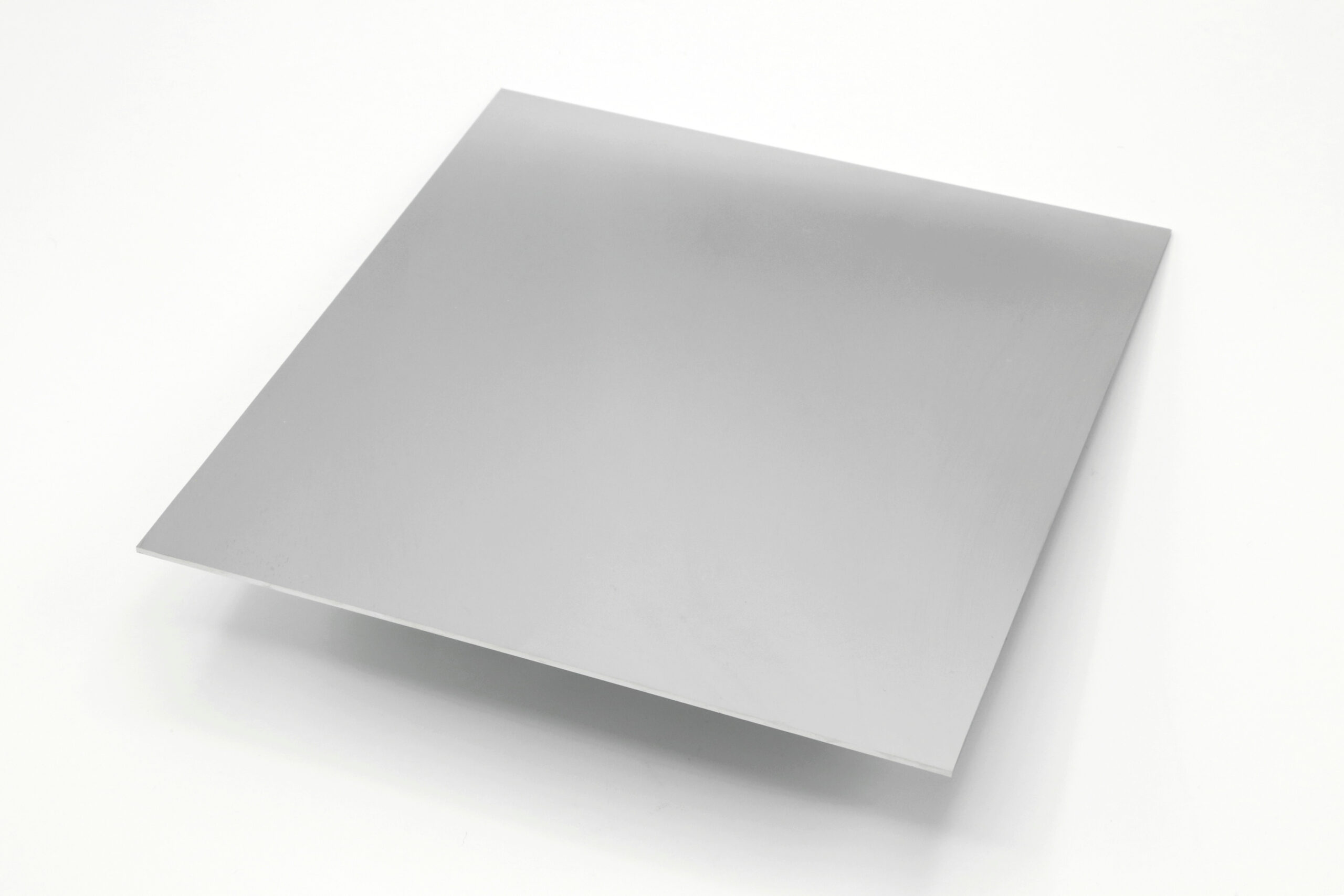

Uniform, pinhole-free coatings for reliable reflectance and tone

Transit-safe packaging to minimize breakage and hidden losses

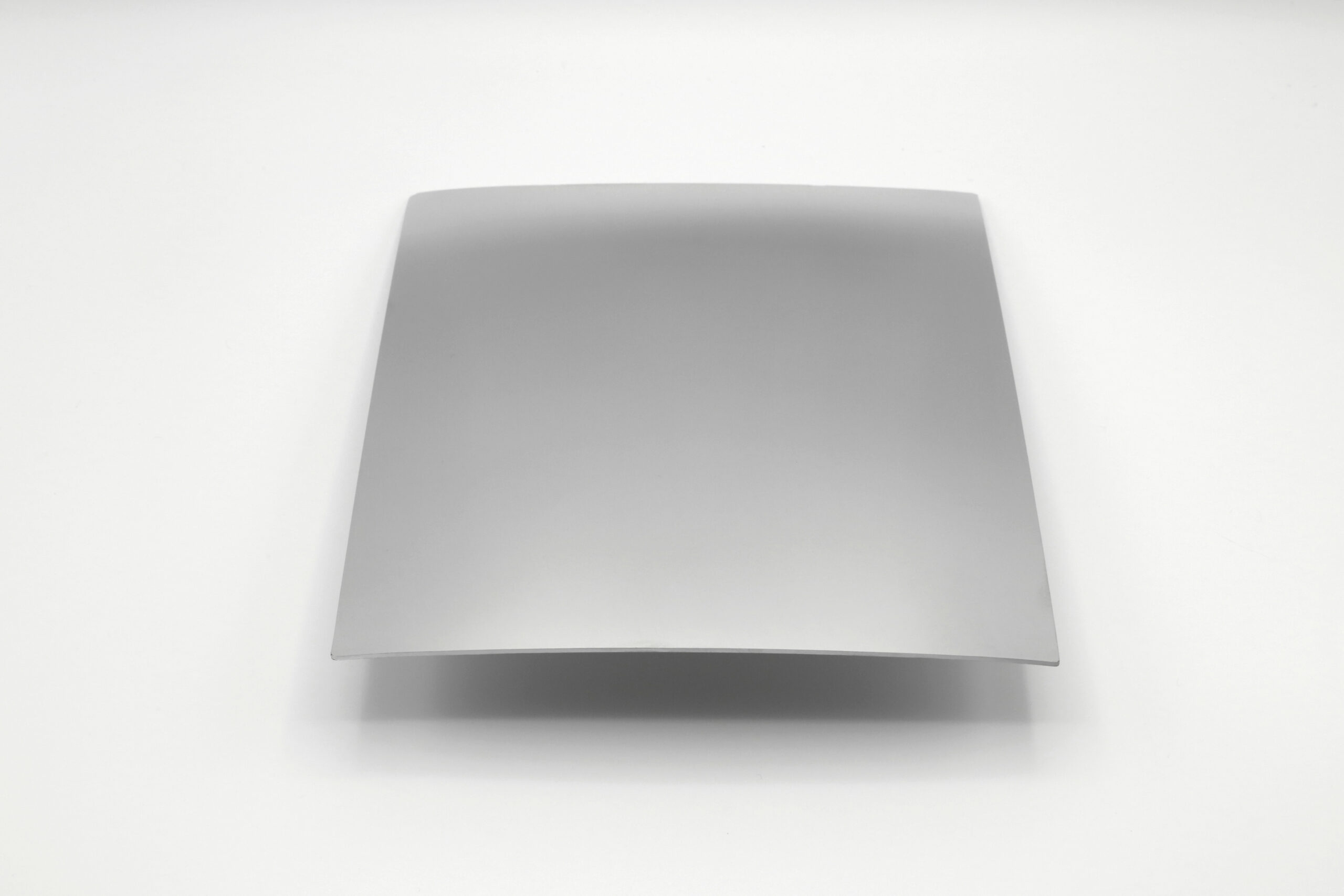

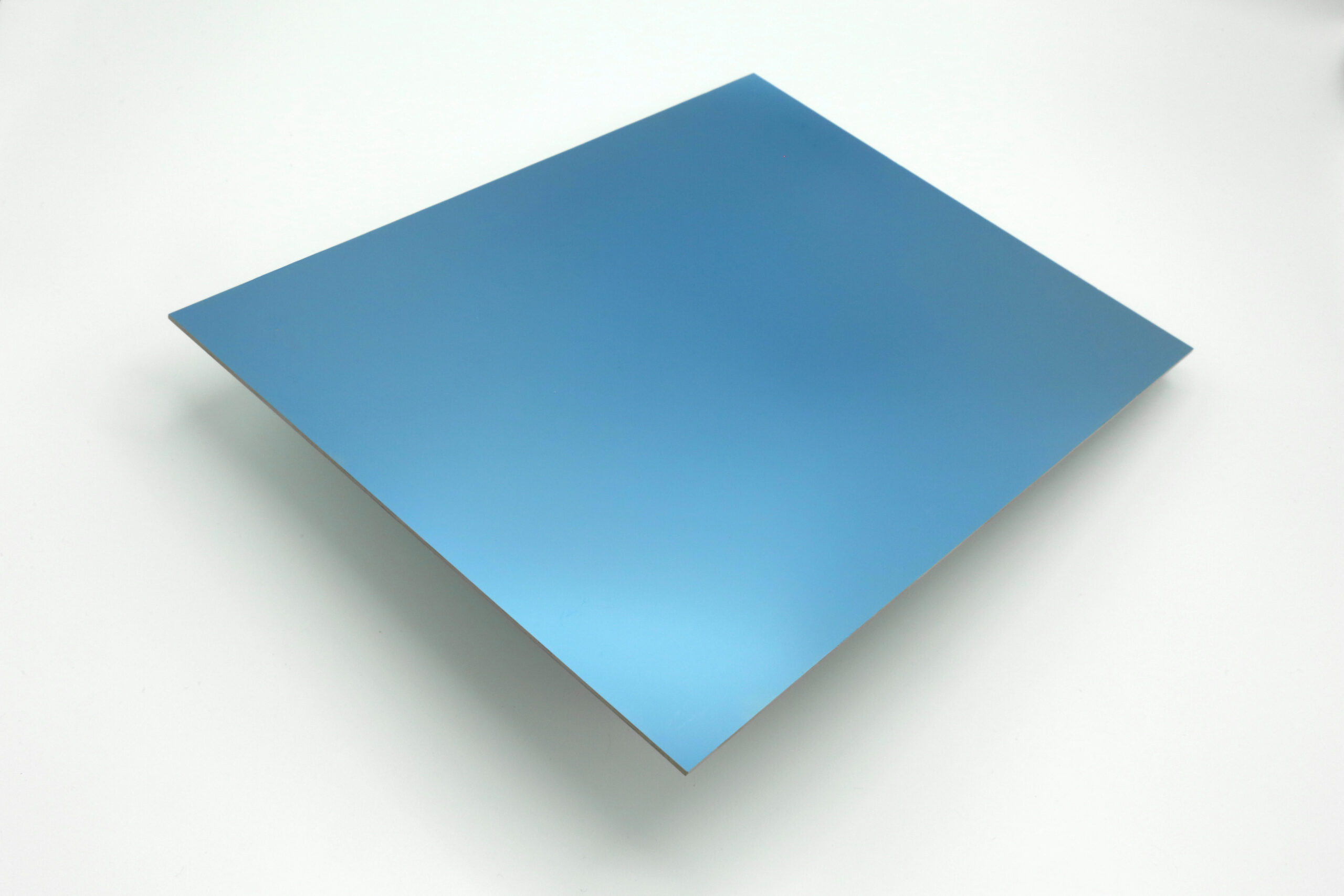

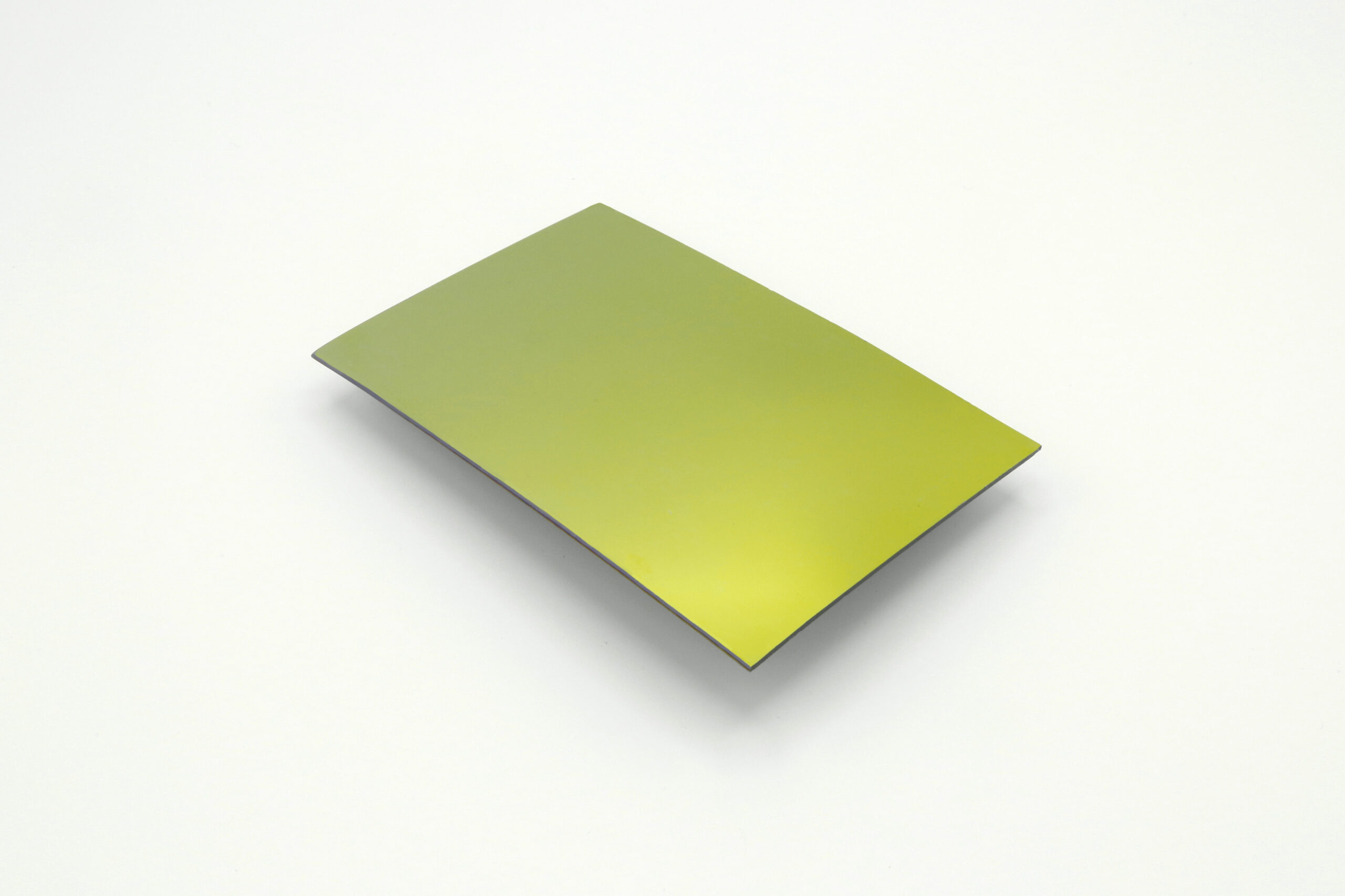

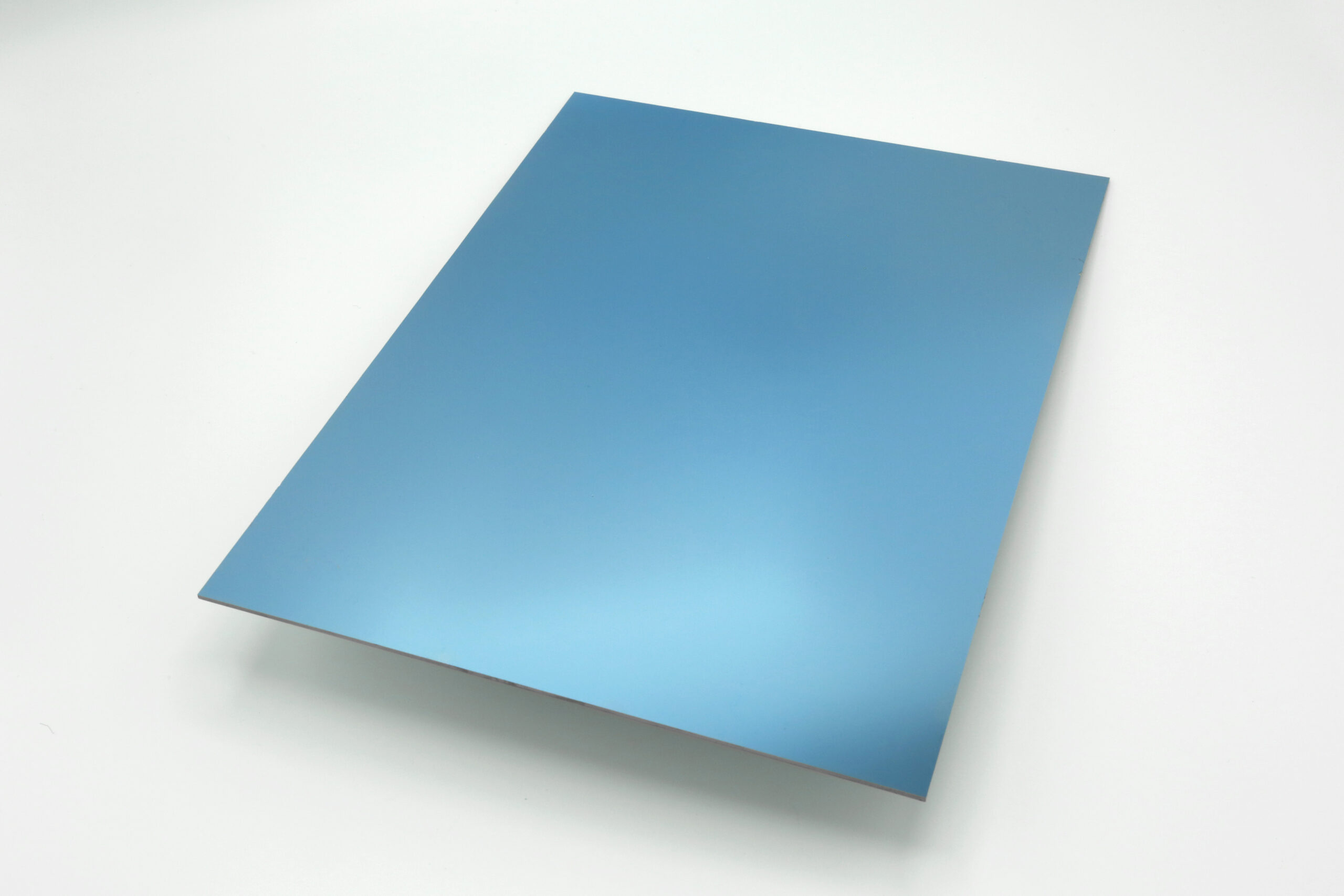

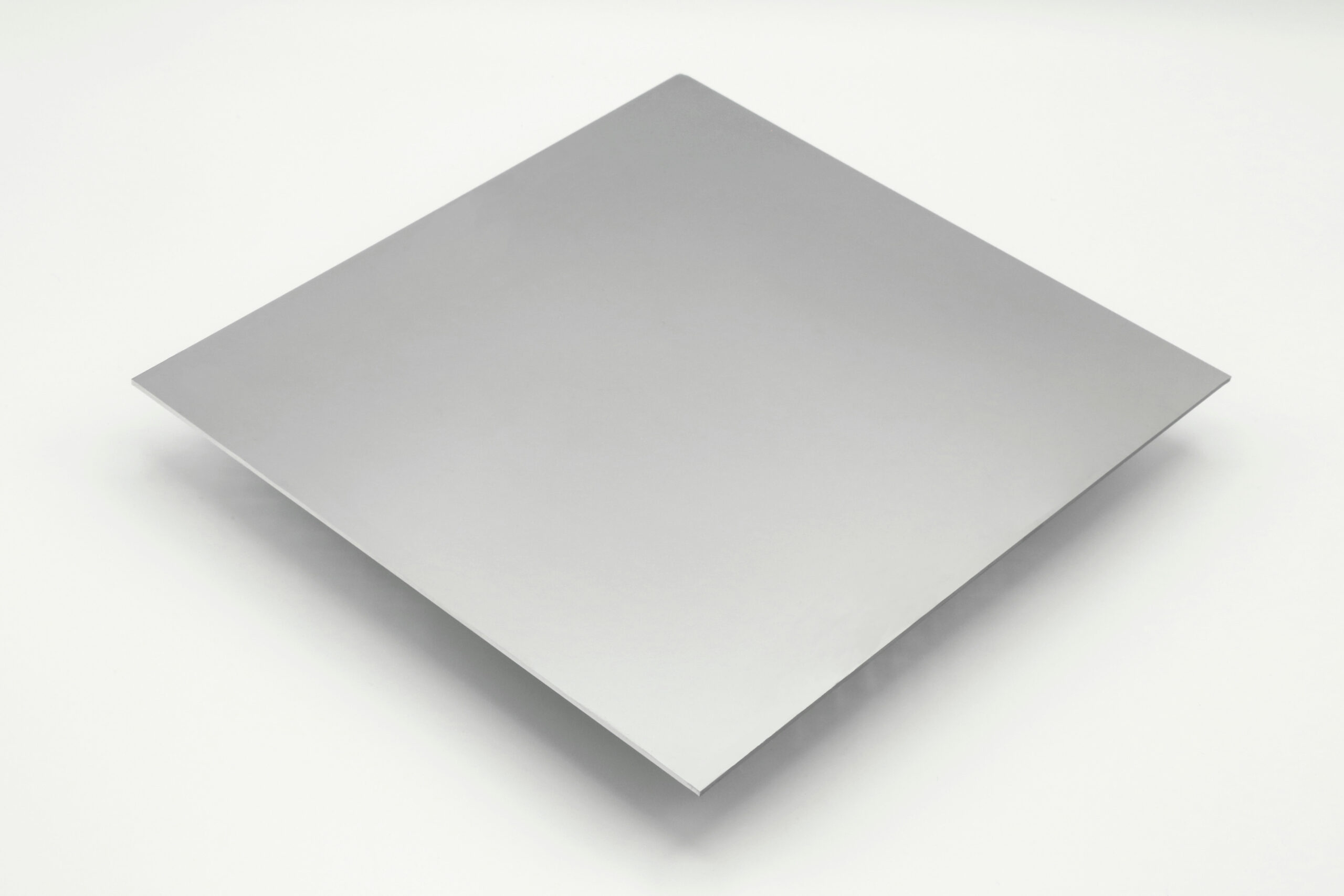

Product Gallery

High-quality flat mirror glass blanks in various configurations

Who It's For

Designed for manufacturers and suppliers who need reliable mirror glass blanks

OEM Suppliers

Automotive/2-wheel/truck suppliers with their own cutting lines seeking reliable flat mirror blanks for downstream processing

Aftermarket Brands

Retrofit/aftermarket brands needing custom sizes and tones for specialized mirror applications

Cutting Shops

Cutting shops without internal coating capability requiring pre-coated mirror glass blanks

Product Highlights

Engineered for maximum efficiency and quality

Size Envelope

Flats up to 407×610 mm for flexible layout and minimum offcut

Coatings

Al / Cr / Blue with tunable thickness per reflectance requirement

Thickness Choices

2.0 / 2.5 / 3.0 mm to balance rigidity, weight, and cutting convenience

Cosmetic Stability

No bubble/white-spot issues; high pass rate

Specifications

Detailed technical specifications for designers and engineers

Designers' Snapshot

Cutting ROI & Quality

Material Utilization

High material utilization reduces cost per cut piece

Coating Uniformity

Avoids rework and visual rejects post-cutting

Transit Safety

Packaging plan supplied with shipments

Process & Delivery

Streamlined workflow from requirements to mass supply

Define Requirements

Size(s), coating, thickness, packaging constraints

Sampling / Pilot

Flat blanks for cutting trials and cosmetic verification

Mass Supply

Stable coating quality, clean cosmetics, consistent batches

Frequently Asked Questions

Common questions about flat mirror glass blanks

What's the biggest flat size I can source?

Up to 407×610 mm per the standard envelope.

Which coating should I pick?

Cr for classic mirror tone and adhesion; Al for high reflectance economy; Blue for premium appearance—thickness adjusted to target reflectance.

What thickness should I use?

2.0 mm for lightweight applications, 2.5 mm for balanced strength and cutting convenience, 3.0 mm for maximum rigidity and impact resistance.

Start Your Mirror Glass Project

Get samples, technical specifications, and engineering support for your automotive mirror glass requirements