Wenzhou Micmirror Industrial Co., Ltd.

A high-tech manufacturer focused on automotive mirror glass

Specialized solutions for passenger-car, commercial-truck and two-wheeler mirror glass. Hot bending × Vacuum Coating × Deep-curvature laser cutting & chamfering × Quality & Lab validation.within IATF 16949 and ISO 14001 to deliver mirror glass that is clear, reliable and traceable.

Clear functional zoning for end-to-end processes

≈2,000 m² processed technical glass daily

3 hot-bending + 3 sputtering + 5 laser cutting

Our Story

Founded originally in Ouhai District, Wenzhou, Micmirror relocated in 2021 to the Waiyang Industrial Zone, Baizhangji Town, Wencheng County, to support expansion and upgrading.

Today we integrate hot bending, sputter coating, laser cutting, cleaning, and testing on one site, serving leading domestic OEM supply chains and extending to Southeast Asia, Europe, South America, and North America.

Second-generation leader Darren Deng continues the founder's spirit with pragmatic innovation, driving technical depth and global reach in mirror glass manufacturing.

Mission • Vision • Values

Mission

Focus on advanced glass processing; pursue technology leadership, superior quality, and customer satisfaction; be a leading provider of professional mirror-glass solutions for the automotive industry.

Vision

Keep pace with intelligent and electric vehicle trends; consolidate mirror-glass leadership while exploring high-value glass applications such as displays and HUD.

Values

Quality first, innovation-driven, and balanced responsibility to environment and society.

Manufacturing Excellence

End-to-end integrated manufacturing process designed for flexibility, scale, and precision

Hot Bending

Curvature-controlled hot bending with 3 automated production lines processing 15,000 m²/day

Vacuum Sputtering

3 horizontal sputtering lines for Al/Cr coating with consistent reflectance and adhesion

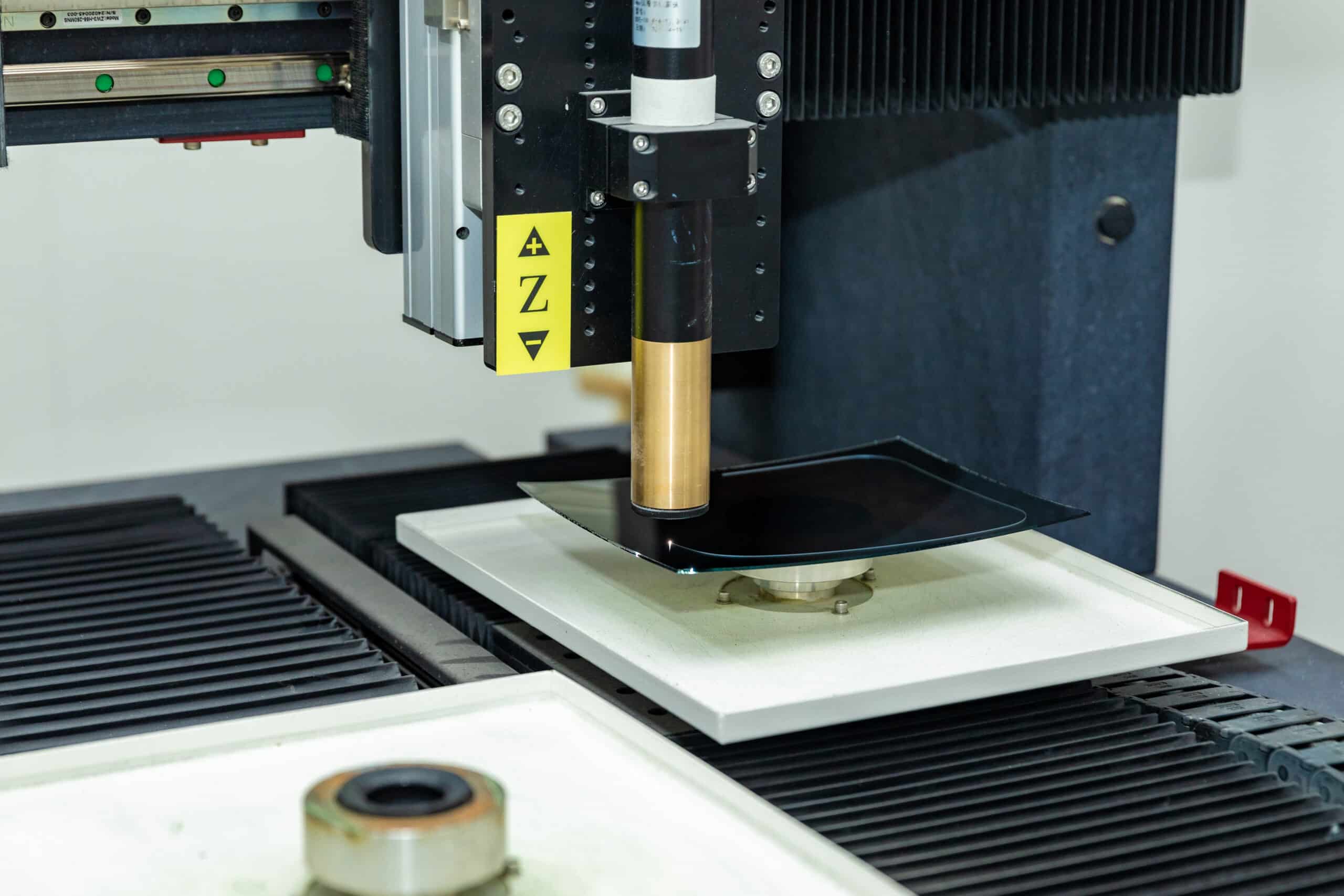

Laser Cutting

5 fully-automatic laser cutting machines for deep-curvature precision cutting

Precision Chamfering

Advanced chamfering technology ensuring no chipping or cracking for enhanced safety

Pure Water Cleaning

Closed-loop ultrapure water system with 10 professional washing machines

Quality Inspection

In-line and offline inspection for optics, dimensions, and surface quality validation

Equipment & Process

State-of-the-art equipment with curvature-controlled hot bending, vacuum sputtering, and precision laser cutting for consistent quality output.

Project Execution

From APQP planning to mass production ramp-up with customized jigs, fixtures, and gauges for OEM programs.

Continuous Improvement

Data-driven optimization focusing on yield improvement, defect reduction, and dimensional consistency enhancement.

Quality & Laboratory

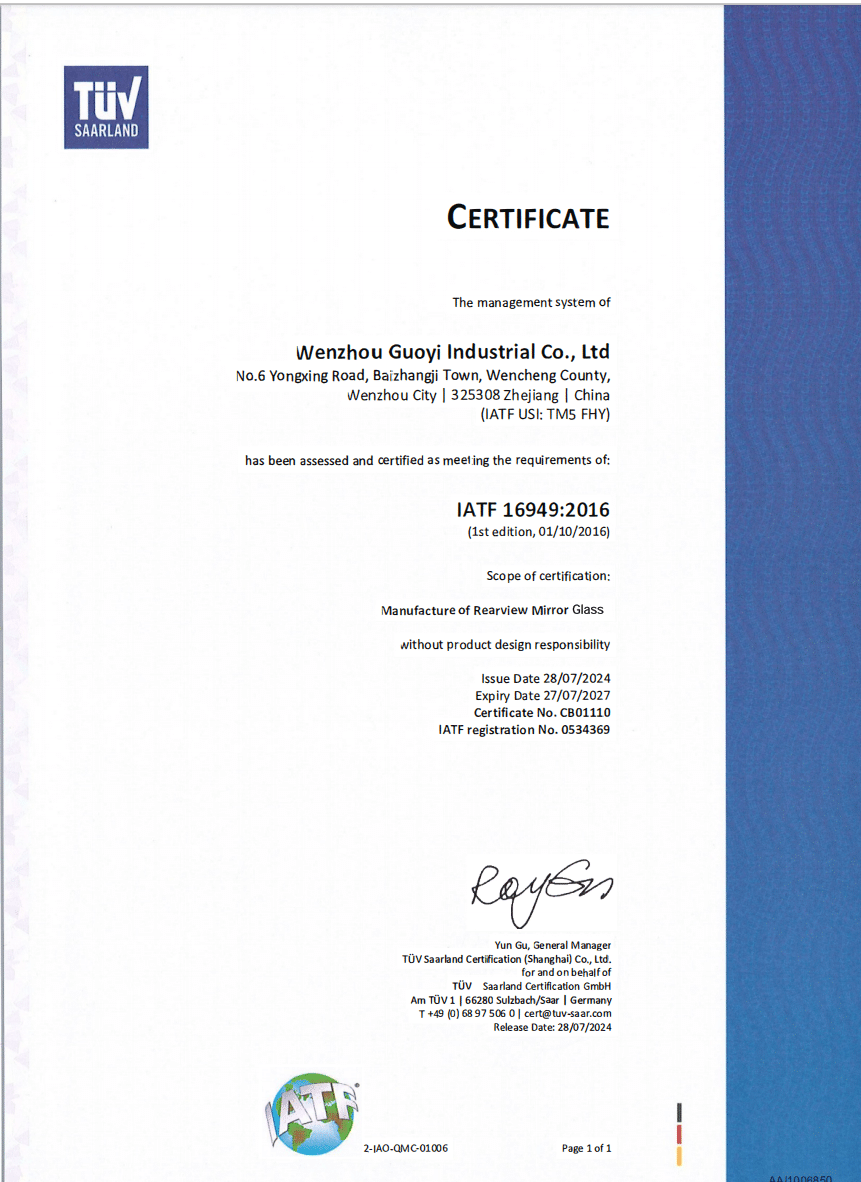

IATF 16949 closed-loop quality system with comprehensive testing capabilities

IATF 16949:2016

Quality Management

ISO 14001

Environmental System

Enterprise Recognition

Quality Loop

Lab Testing Matrix

Our Team

"We take the complexity; drivers keep the clarity."

Darren Deng

Chief Executive Officer

Second-Generation Leader

Darren Deng

Chief Executive Officer

Second-Generation Leadership Excellence

Darren Deng continues the founder's spirit with pragmatic innovation, driving technical depth and global reach in mirror glass manufacturing. As a second-generation leader, he embodies the values of hard work, perseverance, and dedication while steering the company toward intelligent and electric vehicle trends.

Our Culture

A culture of problem-prevention and fact-based decisions, with training, safety, growth, and recognition embedded in daily work. Quality is not only an outcome but a path that starts with people and ends with optical clarity drivers can trust.

Multi-Disciplinary Excellence

A core multi-disciplinary engineering & quality team covers hot bending, coating, laser cutting, metrology & gauges, incoming/outgoing inspection, reliability, and continuous improvement — enabling reproducible quality and stable mass production.

Global Footprint

Wide product coverage across continents, trusted by leading automotive manufacturers worldwide

Southeast Asia

India, Thailand, Malaysia, Indonesia, Philippines

Europe

Germany, France, Italy, Spain, Eastern Europe

Americas

USA, Canada, Brazil, Mexico, Argentina

China Domestic

Leading OEM supply chains nationwide

Trusted by Industry Leaders

Serving major automotive manufacturers with premium mirror glass solutions

Start Your Mirror Glass Project

Ready to discuss your automotive mirror glass requirements? Connect with our engineering team for samples, specifications, and technical support.