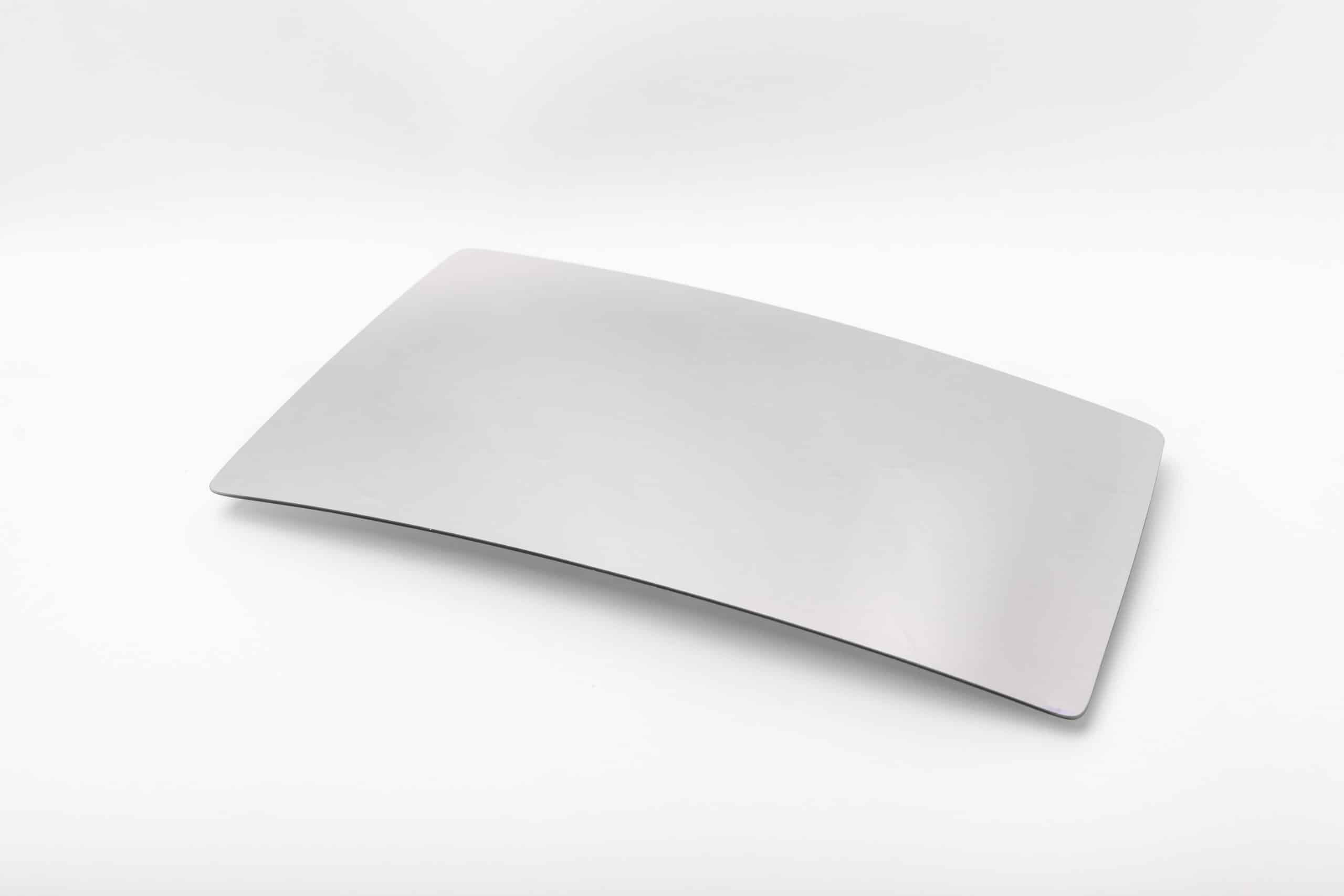

Truck Mirror Glass

Full curvature portfolio for upper, lower, and side mirrors; high-density Cr/Al coatings; deep-curvature laser cutting with precision chamfering.

Extra-wide field of view: tuned curvature sets reduce blind zones in highway, urban, port and off-road scenarios.

Distortion-controlled clarity: high-flatness float glass with stable hot bending—no bubbles, scratches, or white spots.

Assembly-friendly edges: deep-curvature laser cutting + precision chamfering for smooth, crack-free edges.

Built for harsh environments: dense sputtered Cr/Al coatings with strong adhesion, corrosion and chemical resistance.

Variants & Curvature Map

Complete portfolio covering all truck mirror applications

Upper-view Mirrors

Wider side/upward coverage for tall cabs

Optimal for highway visibility and lane changes

Reduced blind spots for urban environments

Lower / Side Mirrors

Precise matching to platform geometry

Glass Thickness Options

Optimized thickness selection for structural integrity and optical performance

Standard Thickness

Cost-effective solution for standard truck applications with balanced durability

Enhanced Thickness

Recommended for commercial vehicles requiring superior impact resistance

Most PopularHeavy-duty Thickness

Maximum strength for extreme conditions and heavy commercial applications

Quality Standard: All thicknesses tested for optical distortion ≤2 arc-minutes and impact resistance per ECE R46

Why It Wins

Customer value delivered through engineering excellence

Safety & Situational Awareness

Wide-angle curvature + high-clarity mirror face produce more complete circumferential monitoring for lane changes, docking, and tight maneuvers.

Assembly Efficiency

Deep-curvature laser cutting and precision chamfering improve dimensional and edge consistency—less rework, smoother fit, better takt time.

Brand Perception

Transparent, clean mirror surfaces and standardized laser markings lift perceived quality on premium commercial vehicles.

Compliance & Traceability

Complete restricted-substances testing with third-party reports plus batch-level traceability streamlines global launches and audits.

Program Support

One continuous workflow—co-development → rapid sampling → pilot validation → ramp-up → stable supply—with PPAP/test evidence/quality docs.

Product Highlights

Technical excellence in every aspect

Optical Performance

High-flatness float glass + controlled hot bending = stable imaging with low distortion; no bubbles, scratches, or white spots.

Deep-Curvature Laser Cutting

Rare capability for large curvature parts with smooth, crack-free edges and high-consistency chamfers.

Durable Coatings

Vacuum sputtered Chromium / Aluminum for dense layers, strong adhesion, stable reflectance and pure chroma; resistant to salt/corrosion and acids/alkalis.

Frequently Asked Questions

Get answers to common technical questions

How do I choose between the upper and lower/side curvature sets?

Use R1800–R2000 / R1400–R1500 for upper-view coverage; for lower/side choose from R120–R1000 to tune near-field awareness, docking angles, and regulatory markings per market.

Can you handle very large mirrors without edge defects?

Yes—our deep-curvature laser cutting + precision chamfering targets crack-free, burr-free edges even on large formats (up to 480×250 / 457×305 mm).

What documents are provided for OEM projects?

Third-party restricted-substances reports, material compliance, batch traceability, and the PPAP set (with test evidence) to support SOP.

Start Your Mirror Glass Project

Get samples, technical specifications, and engineering support for your automotive mirror glass requirements